Description of Chromium Carbide Overlay (CCO) Wear Plate

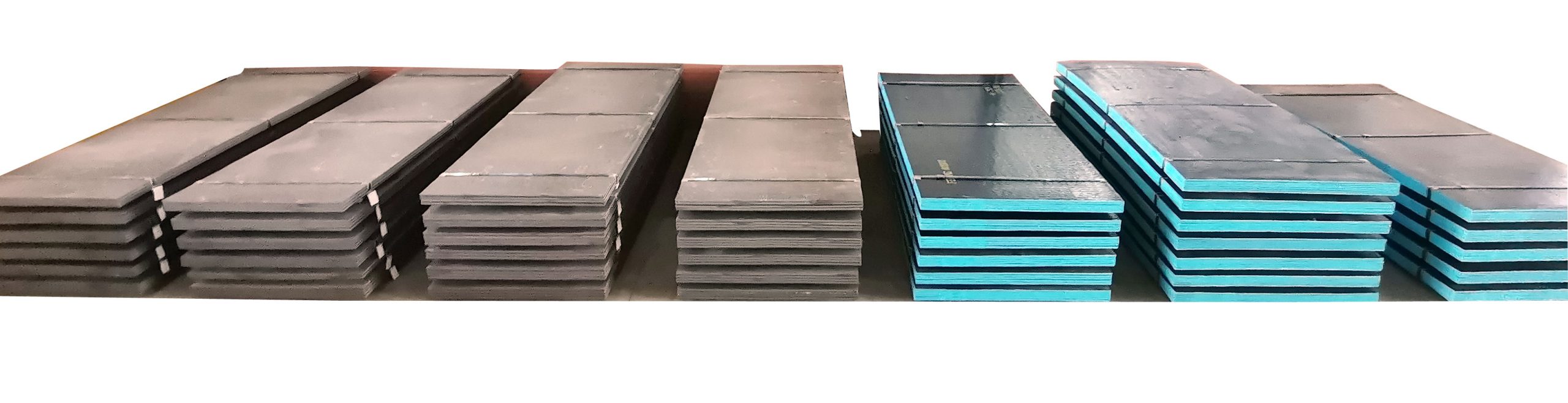

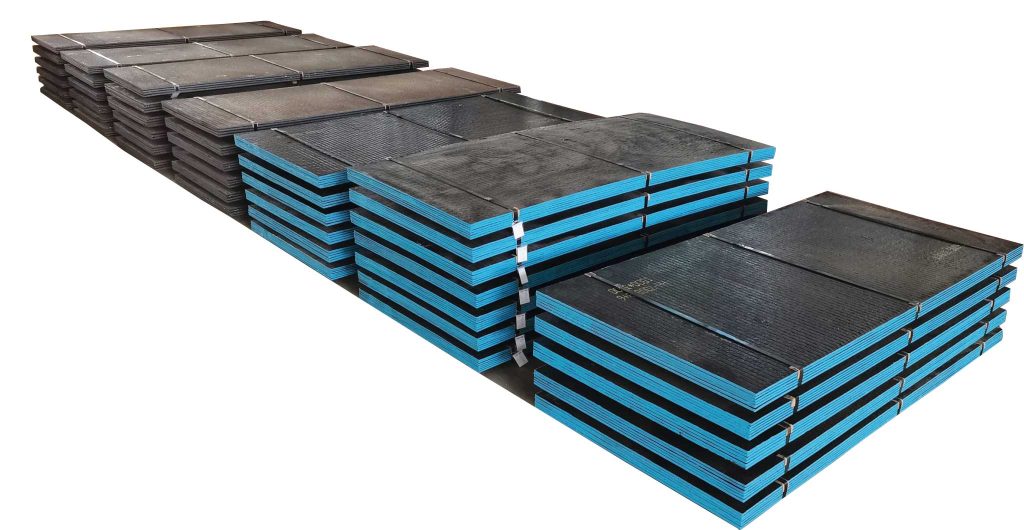

Chromium carbide overlay wear plates also known as CCO plate, Chrome carbide overlay wear steel plate, Bimetallic wear plate/sheets, Bimetal plate, Welded overlay plate, Hardfacing wear plate, Composite wear plate, Hardfaced wear plate, Cladded wear plate, Fusion wear plate, etc.

Our chromium carbide overlay wear plate are manufactured by welding the high-chromium high-carbide alloy onto a mild steel base plate.

1) The mild steel base plate has toughness, easy welding performance, supports the overlay layer, bears structural stress, and connects with other parts.

2) The chromium carbide overlay layer contains up to 35% chrome and up to 5.5% carbon which makes it extremely hard and highly abrasion resistant.

3) The welding process is automatic open arc welding. This process is a kind of metallurgical fusion, so the alloy layer and mild steel base plate will not separate or corrode and is resistant to high heat.

Application Of CCO Plate

1) With high abrasion, corrosion resistance, and medium impact performance, FEHONG’s CCO plates are extremely applicable for serious working conditions.

2) Our plates are widely used for making many kinds of wear parts for construction machinery, metallurgical machinery, cement plant, mining machine, thermal power plant, and coal yards.

3) Our CCO plates can effectively prolong the service life of related equipment, reducing their downtime and maintenance.

Advantages Of Chromium Carbide Overlay Plate

- The overlay alloy has a high amount of chromium carbide hard particles

- The carbides are distributed vertically on the wear layer surface in the form of fibers and are evenly distributed

- Top anti-abrasion performance

- Good impact resistance

- Good formable performance

- Easily welded to most weldable steel

- Various thicknesses of CCO plates are available

- Less downtime

- Lower maintenance cost

- Prolong service life

As you can see in the below picture, the overlay alloy has a high amount of chromium carbide hard particles, and the carbides are distributed vertically on the wear layer surface in the form of fibers and are evenly distributed.

The white part things are primary carbides.

SGS Chemical Analysis And Hardness Test Report

1) Primary M7C3 carbide hardness: 1400 – 1800 HV

2) Primary carbides volume fraction: over 60%

3) Macro-hardness: ≥60 HRC

(for wear-resistant layer over 10mm)

Other Features of Chromium Carbide Overlay Wear Plate

- Microstructure: The primary carbides (M7C3) volume fraction is above 50%

- Rockwell Hardness: chromium carbide hard particles are distributed evenly throughout the overlay, and the carbides are distributed vertically on the wear layer surface in the form of fibers which creates a strong microstructure. The CCO plate’s hardness is between 55-64 HRC, depending on the overlay’s thickness, such as welded thickness over 12 mm, and hardness over 62 HRC.

- Wear resistance: Our test shows that the abrasion-resistant performance of chromium carbide overlay plate ( CCO plate ) is 20X higher than mild steel and 8X than heat-treated steel.

- Flatness tolerance: ±3 mm/m.

- Thickness tolerance: uniform overlay thickness, tolerance within 0-0.3mm

Specification of Chromium Carbide Overlay Plate

FEHONG chromium carbide overlay plates are available in several grades to suit a range of operation conditions:

HH-700B: suited for applications involving high abrasion with moderate impact.

HH-750B: suited for applications involving severe abrasion and moderate impact.

Base material: mild steel, Q235, Q345 or A36

Main Chemical compositions of welded deposit (3 pass welded) | ||||||

Type | C | Cr | Si | Mn | Ni,V,Ti, Mo, Nb,W | Hardness |

HH-700B | 4.8-5.5% | 23-28% | 0.7-1.5% | 0.6-1.0% | suitable | ≥60 HRC |

HH-750B | 5.0-6.0% | 25-32% | 0.7-1.5% | 0.6-1.0% | suitable | ≥60 HRC |

HH-850A | 5.0-6.0% | 35-40% | 0.7-1.2% | 0.5-1.0% | suitable | ≥60 HRC |

HH-80pro | 5.0-6.2% | 20-25% | 0.7-1.2% | 0.4-0.8% | 5.0-6.5% | ≥60 HRC |

Standard Dimensions of Chromium Carbide Overlay Plate

Thickness | Size | Cladded area |

3 on 3 | 1000×1500mm | 1.5 sq.m/sheet |

3 on 5, 4 on 4, 4 on 6 , 6 on 6, 4 on 8, 5 on 8, 6 on 8, 7 on 8 | 1480×3041mm | 4.5 sq.m/ sheet |

8 on 8, 8 on 10, 10 on 10 | 1470×3062mm | 4.5 sq.m/ sheet |

12 on 12 | 1460×3083mm | 4.5 sq.m/ sheet |

Note: 1400×2900 mm, 1400×2850mm, 1500×3000mm, 2000*3000mm, and 2100*3100mm plates are also available.

Other thicknesses and dimensions can be customized.

We can also cut, bend and weld the chromium carbide overlay plate into specific shapes and parts, as well as keep the good flatness.

Numerous Fixing and Assembly Processes Are Available

Welding and cutting processes do not affect the wear resistant properties of the FEHONG CHROMIUM CARBIDE OVERLAY PLATE. Matching welding wires are also available for the protection of internal joints and seams.

Chromium carbide overlay plate can be cut and formed easily.

♦ Drilling Holes

Straight holes and countersunk holes.

♦ Bolt Embedded Welding in the Back

Embedding the pre-processed bolt in the back of the wear plate.

♦ Bending

Chromium carbide overlay plate can be cold formed and made into a curve of the cone.

♦ Welding

Chromium carbide overlay plate can be welded and assembled into kinds of wear parts.