HH-808s hardfacing FCW welding wire for Crusher

Charateristics

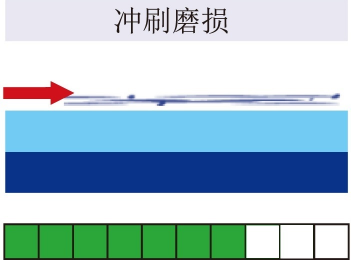

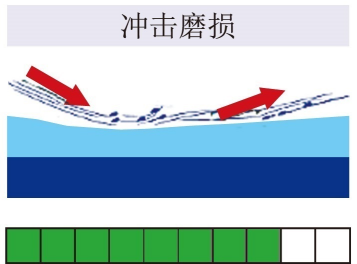

HH-808s is a high-performance flux cored welding wire, it produces an overlay resistant to abrasion and impact. The weld deposit cannot be machined. The weld material exhibits cracks。

Microstructure: High-chrome-high-carbon complex carbide alloy: C – Cr – Mo – V – Nb – Ni – Fe.

Machinability: Grinding only

Deposit thickness: Not suited for flame-cutting

Deposit thickness: Multi layers.

Application

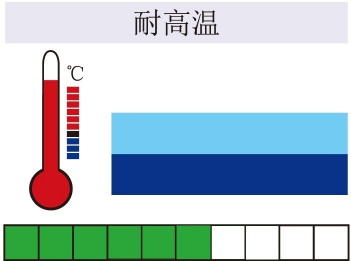

Perfectly suited for parts subjected to combined impact and abrasive stresses, e.g. cone crushers, pick hammers, dredger teeth, crusher roll and guide rails. The application temperatures should not exceed 450℃.

Typical compositions of pure welded deposit (3 layer welded )

| C | Cr | Mn | Si | Mo、Nb、V、Ti、W、B+other | |||||||||

| 2.0-4.2% | 20-25% | 0.6-1.0% | 0.7-1.2% | 4.5-6.0% | |||||||||

Hardness of pure welded deposit: ≥ 50 HRC

Package: 15 kg / spool

Recommended welding parameters

Amperage [ A ] | Voltage [ V ] | Wire stick-out [ MM ] |

360-430 | 29~32 | 25~40 |

*This data sheet corresponds to the present state of production (August 2023) and can be changed anytime.