HH-850A Hardfacing FCW Welding Wire for CCO Wear Plate

Ultra-high chromium wear-resistant plate flux cored wire, less welding spatter, smooth welded deposit smooth , high welding efficiency and high recovery rate.

Charateristics

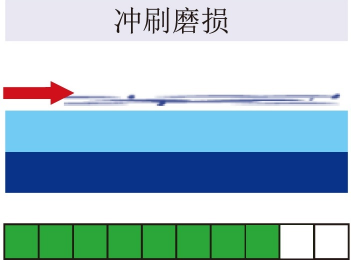

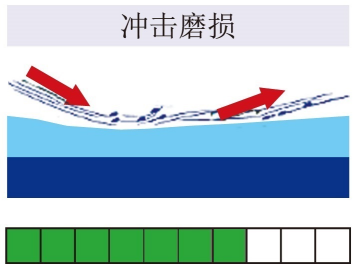

HH-850A produces a wear-resistant, primary carbide-containing weld deposit. It is very resistant to abrasion.

Microstructure: Ultra high-chrome-high-carbon hard alloy on iron base: C – Cr – Fe.

Machinability: Grinding only

Cutting: Not suited for flame-cutting

Deposit thickness: 30 mm in Multil layers.

Application

Recommended particularly for the produce Chromium carbide overlay wear plate(CCO wear plate, or Bimetal plate) or wear resistant pipe, can also be used for hardfacing chutes, sieves, conveying channels, liners,hoppers.,etc. The application temperatures should not exceed 450℃.

Typical compositions of pure welded deposit (3 layers welded )

| C | Cr | Si | Mn | Ni,V,Ti, Mo, B,others | |||||||||||

| 5.0-6.0% | 35-40% | 0.7-1.2% | 0.5-1.0% | suitable | |||||||||||

Hardness of pure welded deposit: ≥ 60 HRC

Package: 250 KG / drum ,125 KG / drum

Recommended welding parameters

| Wire diameter [ MM ] | Amperage [ A ] | Voltage [ V ] | Wire stick-out [ MM ] | ||||||||||||

| 2.8 | 360-450 | 29-33 | 25-40 | ||||||||||||

*This data sheet corresponds to the present state of production (August 2023) and can be changed anytime.